X-ray Mirror Laboratory: Facilities

X-ray Mirror Laboratory: Facilities

The X-Ray Mirror Laboratory is located mainly in Building 2 of the Goddard Greenbelt Campus, devoted to research and fabrication of X-ray foil mirrors. A large facility in Building 22 houses additional equipment for the research of thin glass reflectors for the Constellation-X project. Facilities in Building 2 include a foil preparation room, an optical laboratory, a mirror foil replication laboratory, and 2 metrology labs. We also use the X-Ray Astrophysics Laboratory's long X-ray beam facility located also in Building 2.

Foil Research and Preparation Clean Room

Bare Aluminum foil are prepared mainly in the Foil Research and Preparation Room. Most of the mechanical processes for bare foil preparation are completed here. Equipment and processes preformed in these room includes:

- Mechanical Cutting stations. These stations are used to cut foils at various stages of production, including cutting flat aluminum pieces from large sheets, cutting flat pieces into forms with precise arc-shaped boundaries, and trimming conically shaped foils.

- Ultra-sonic baths. Baths containing orgainic solvents are used to clean metal sheets in ultra-sound.

- Mechanical rollers. Sets of rollers are used to shape foils into approximate conical configurations.

- Vacuum equipment and ovens. These are heat forming equipments with which the foils are formed into precise conical shapes.

Optical Laboratory

Bare and replicated foils are examined by optical means for quality. The examination involves a series of processes and instruments, for examination of roughness and waviness in different wave lengths. Most of the instruments are housed in the clean room (class 10,000) in Building 2. They include:

- Optical beam sources

Wide parallel beams in white light and in monochrome are used for a variety of experimentation, in particular, as source for testing the mirrors in and out of telescope housings. The mountings are such that vertical beam and horizontal beam are available for various orientiation of the telescopes. A auto-collimator is used to calibrate the parallel beams.

- Laser sources

Different laser sources are used as narrow pencil beams for examination of surfaces of glass and foil mirrors.

- Video monitoring system

A video camera and a monitor are used to study mirror responses. This is particularly useful for tuning the telescopes, or sections of them.

- Optical low-power detectors

Solid state detectors are used for light intensity measurements. These are low power detectors with nW sensitivities. Apertures are applied in front of these detectors measurements of light intensity distributions.

- Charge coupled device and image analysis system

A liquid-cooled CCD camera is used for image acquistion. Telescopic images are analyzed with supplied software on a SGI platform.

- Microscope

A phase-contrast microscope with magnification up to 500X is used to examine surface roughness in sub-millimeter wave length.

- Laser scanning micrometer

The system utilizes infrared laser mounted on motorized stages to scan surfaces up to 200 mm in length. Both the detector and the motorized stages have resolutions of 0.1 mircrometer and the system is used for examination for large scale waviness and micron level roughness simultaneously.

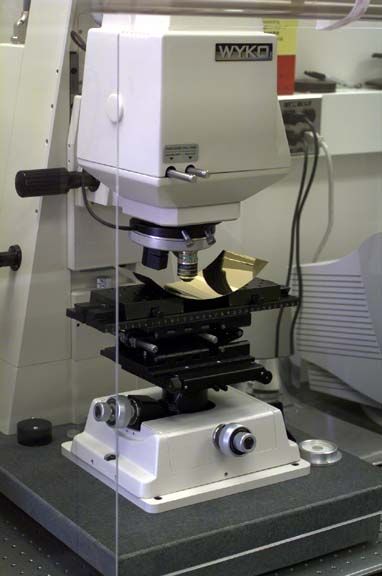

- Optical interferometric profiler

The system is fast and efficient in surface roughness measurements and analysis. We used a WYKO RST plus system which consists of several objectives on turret, up to 50X. Interferometric data are converted into surface profile on a chip with a 236x368 format. The view of field is sub-millimeter, depending on the magnification. The depth resolution is 0.05 nm, if a good vibration isolation is provided. Both the data acquistion and analysis are done on a PC platform.

- Alignment station

The station is used to align the optical axes between the foil mirrors and the telescope housing. Two travelling microscopes are positioned on each side of a motorized axle, on which a telescope housing can be mounted. Viewing is through video monitors. The resolution is 0.01 mil. Vibration isolation is provided by a massive granite platform.

Foil Replication Laboratory

Actual foil replication are done in the foil replication laboratory which is located in the basement of Building 2. Pre-replication foils are transported from the foil preparation room to the replication lab for temporarily storage; and replicated foils are sent to the optical laboratory for examination and qualification. The replication lab handles processes such as preparation and spraying of epoxy, sputtering of metal onto glass for replication, replication, curing, cleaning and others. Equipment of the laboratory include:

- Spray booth. Spray guns are mounted inside the ventilated booth, on motorized stages and platforms. Aluminum foils and gold-coated mandrels are positioned on the platforms for spraying. The processes is automated except for loading and unloading of epoxy, foils and mandrels.

- Sputtering system. A hollow cathode sputtering system is used to coat metallic gold onto glass mandrels. The system consists of a 42 inch (diameter) vacuum vessel, a pumping system, a 10 kW DC plasma generator and a control console. The pumping typically achieve a few micro-torr with a mechanical pump followed by cryopumping. The sputtering is done in Argon medium in the water-cooled steel vessel. The process of pumping, sputtering and venting, in sequence, is automated. Argon control is also automatic.

- Replication Chamber. The replication is carried out in a vacuum chamber which a large transparent window and inside which a motorized stage is seated.